I have spent the last few days speaking with my friends here in Houston, and I emphasize the word FRIENDS as I have never been more proud of these local fashion designers/manufacturers. They have not skipped a beat to come to the rescue of our amazing medical providers, first responders and those most in need in our community that could not get access to much needed protective gear. There has been much conversation on the news about how deficient we were (our country, but we do have the largest medical facility here!) and still are in providing PPE (Personal Protective Equipment) but for me, it was not until I spoke to Chloe, Megan, Ahshia, Sara-Jayne and David that I understood the scope of what the need was and how these few people are stepping up to do their part to come to assist as they can.

For Chloe Dao, (http://chloedao.com) Project Runway winner and one of Houston’s most well-known and beloved designers here for all that she does for our city, she had her own emotions to deal with that Coronavirus brought on. She was faced with, not planning the 20th anniversary that she was about to have of her business but to have to shut it down abruptly. She was still spinning in that mode, when the idea hit her to immediately make 100 masks for the community, primarily for her Instagram followers. She researched mask patterns and dove in. What originally started with that 100 that she was giving away free, grew to dozens, then hundreds of messages, emails and phone calls came in. It was then that she began giving them to individuals that had either elderly or ill family to care for, and found that many of her followers worked in hospitals and clinics all over the city and the country. That was just over a week ago and they have been working non-stop since then.

She and her team have produced over 700 for the first Friday pick-up, another similar quantity for this past Friday and she is moving forward with thousands of requests both locally and from all over the U.S. Her masks are made of washable cotton and have a pocket designed to fit over the N95 required masks. They are washable and can be re-used and says that even though they are not N95 quality, she is filling a need that in many cases were only filled by scarves. She, luckily, due to her size and notoriety has vendors that she works with in L.A. as well and getting mask-making supplies from many places. She is producing about 150/day and the great news in this is also that because the demand is so high, she is able to continue to employ all of her staff in her Heights studio as she has more than enough for them to do. Pick-ups are weekly at her Rice Village store. It just keeps growing each week. In fact, demand is so high that she has to limit to 4/household and is also getting requests for an upgraded mask made from her premium fabrics from her collection. She is starting those for sale of $12-$18 each in addition to the free masks that she is providing. To help: you can donate to Chloe and her team here by giving $10 each or more to help keep them going.

For Sarah-Jayne Smith and Ashia Berry of the internationally recognized non-profit design house, Magpies & Peacock(https://magpiesandpeacocks.org/), a collaboration with Clarence Lee, a Board Member of theirs and a Designer at local ready-to-wear fashion label, Inclan Studio(https://inclanstudio.com/) a collaboration was the best route to get going quickly to help our community with masks. They decided on upcycling together and create non-woven polypropylene masks, which will be distributed directly to Houston-area hospitals. Because of their association with the Houston Arts Alliance and Visit Houston, this trio of creatives was able to take promotional products like washable poly bags from the Super Bowl days and other items and re-purpose them into masks. This partnership of two gals that are known for their amazing repurposing of post-consumer textiles and Clarence’s design skills they were able to find materials, and design them to meet the requirements of N95 three-ply masks. They then turn all of this over to their teams of sewers that take the materials and design home and produce the hundreds of masks that these ladies are able to funnel to the Med Center……the entire process as they described it to me was fascinating and courageous! To help: there is a mask campaign established that you can make donations to to help these ladies and their teams of home sewers continue to produce the volume needed for our medical community.

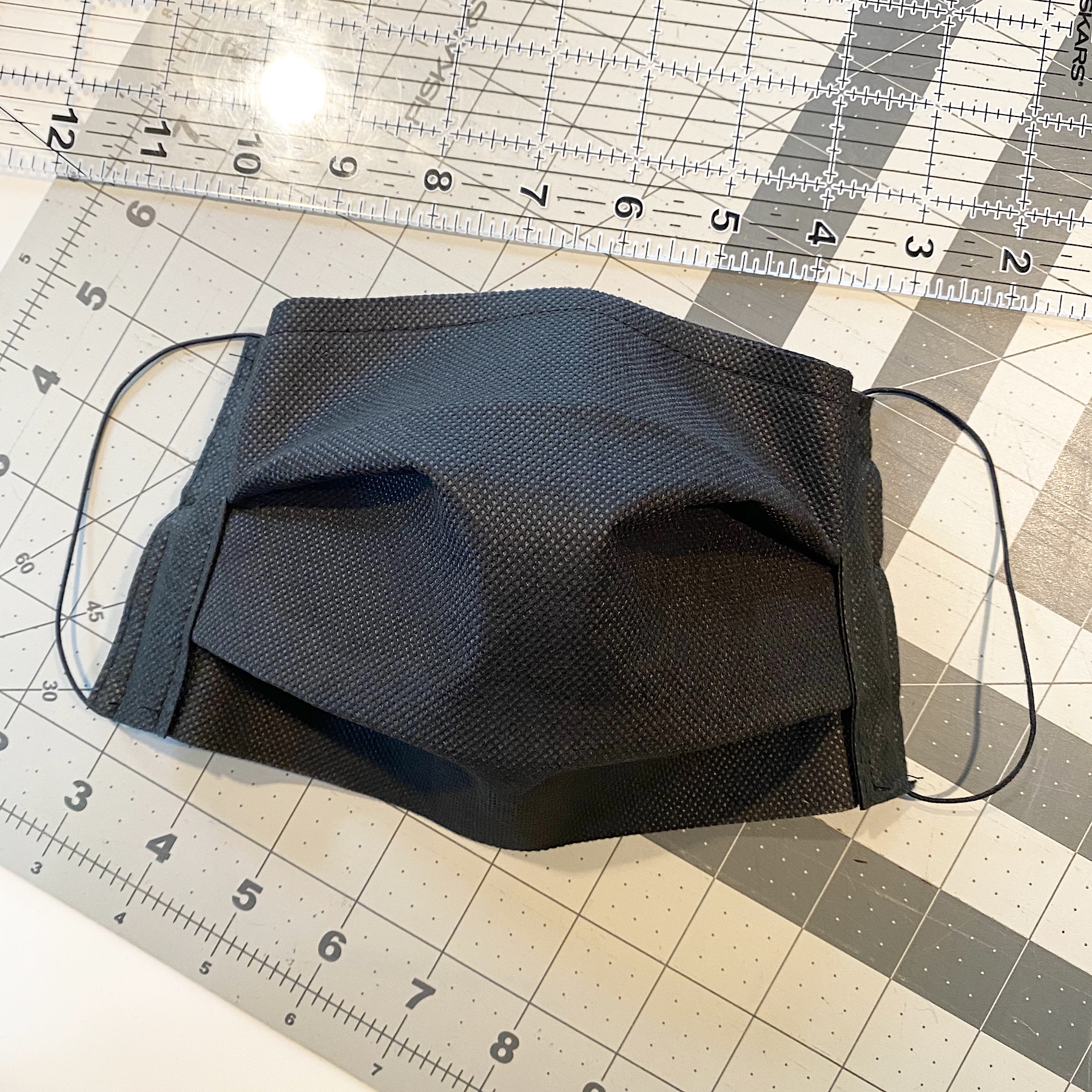

Most recent, as of this past week, to join the Mask makers here in town is one of Houston’s most beloved fashion designers, David Peck. He has begun in earnest to produce in his studio for Monday’s first delivery, his first batch of 1,250 #Coronavirus masks. They are made of a non-woven polypropylene fabric. They have a pocket inside into which a HEPA filter can be inserted, a nose wire and elastic at the chin for optimal fit. They are designed to fit over an existing N95 mask, hopefully prolonging the life of these masks for our medical community.

David has requested that if you know of any institutions that are in need of supplies, please email alyssa@shopdavidpeck.com. To help: Please consider making a donation of $10 to help David and his team continue production. The money will help purchase supplies and fund the workers that are needed for production.

Last but certainly not least in this group of local mask-makers is a lady that many of you may not have gotten to know yet, but hold on, as you will very soon. Her name is Megan Redding and she is the founder/designer of Accel Lifestyle which is a new athleisure line made of an amazing anti-bacterial fabric, also developed by Megan, who is first and foremost a scientist. Her fabric is anti-bacteria which she has designed into very stylish fashion pieces but the key to her collection (which I first purchased at a Tootsies trunk show of hers) is that because of the weave of this anti-bacterial fabric, it can be worn repeatedly and not cause any perspiration odor. Her collection is awesome and worthy of another story altogether. However, this anti-bacteria fabric is perfect for this need.

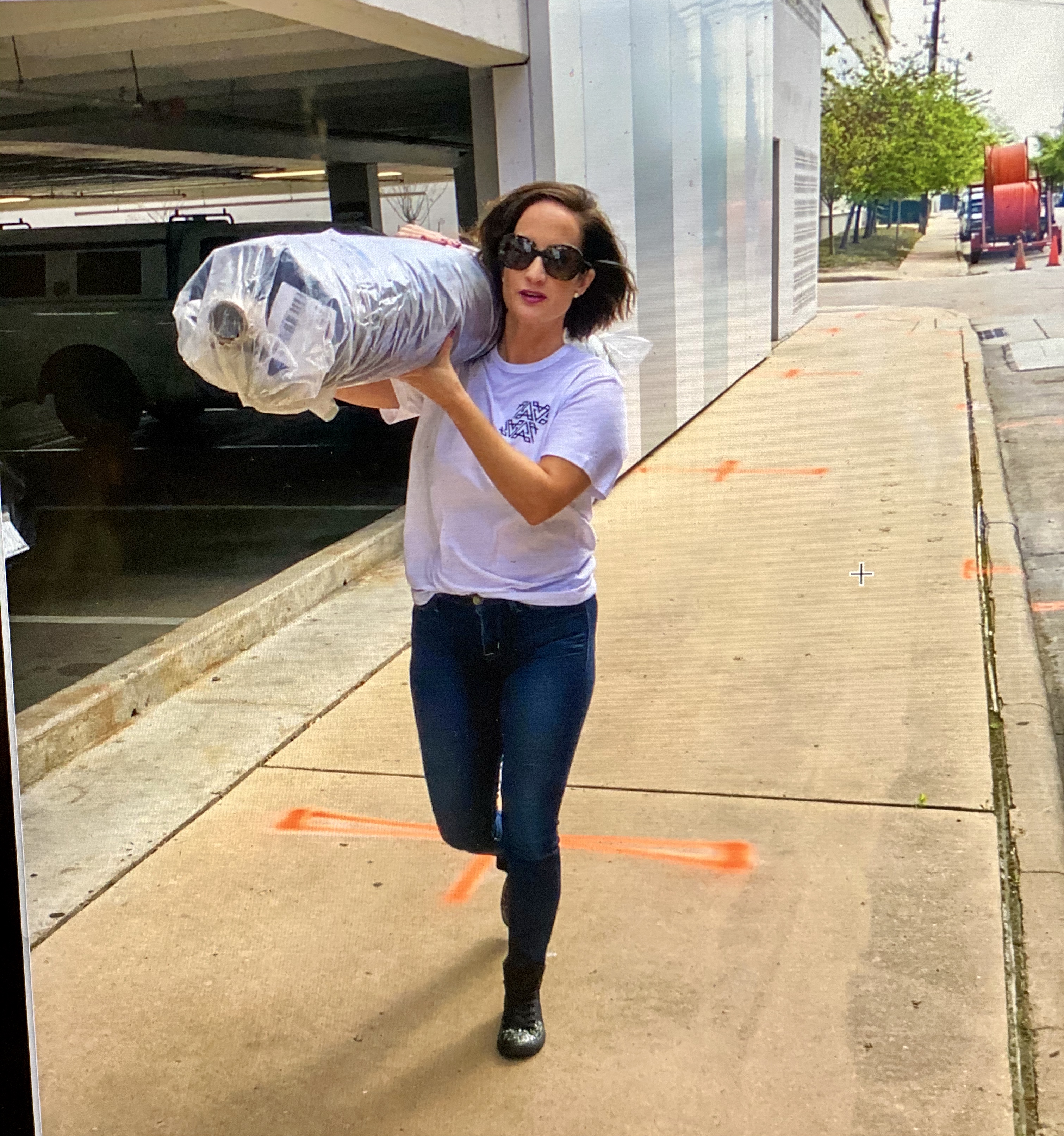

Because she is the maker of her own fabric and has factories and workers at her disposal, Megan took last weekend and secured the yardage from her L.A. and North Carolina factories, created multiple patterns, found all necessary trim items and was ready to be in operation immediately. She is creating these sturdy double-layer masks that she is making out of her midtown studio and will have at least 2400 available by Monday, 9,000 for the weekend and capabilitiess of up to the tens of thousands. She is working with all of the Supply Chain Directors from every major medical facility and will be ready to supply them with their needs at what seems to be a fair price. Knowing Megan and her high-energy, do-it-and-do-it-now mentality she will become a major supplier for our Med Center and beyond. When asked why she was doing this, her response was, “I am blessed to be able to do this and to help those health care workers on the front line”!

**In closing I must say that I was eager to do what I could in my small way to help these local entrepreneurs who have their own problems of being a small business to deal with. Donations in any amounts…..they can start at $10 would be great and if you are handy and can become a home sewer or maker of these masks to help, each of the first three have tutorials on their websites and ways to reach them if you can help. I know anything would be greatly appreciated by all that I have written about here and for the many health care workers that are putting their lives on the line for all of us!!!

Help Chloe, David, Megan and Ashia, Sarah-Jayne, Clarence continue to help our city!!

Thank you sweet Roz!!

I look forward to seeing you when this is all over 🙂 🙂

Big Hug,

Megan